Tower Dryer

Sukup's Tower Dryer is well-suited for feed mills and larger farm installations.

Our Tower Dryer is a stationary drying system made from materials such as stainless steel and equipped with industrial fans/burners for continuous operation year after year.

The Tower Dryer provides a very high drying capacity and can handle most crops such as rapeseed, grain, corn, beans, etc.

Like our other dryers, it is fully automatic in all functions and controls the moisture content by continuously measuring the humidity in the crop.

As standard, the moisture content is measured both at the inlet and at the outlet, ensuring full control over the drying process.

The dryer is easily operated via the included “QuadraTouch Pro” touch panel, which can be mounted at the dryer or in a control room away from the dryer.

Specifikations

- Capacity up to 200 t/h

- Uniform drying/quality ensured with the Grain Cross-Over System

- Easy cleaning where varietal purity is required

- Integrated heat recovery ensures low energy costs

- Very low noise level

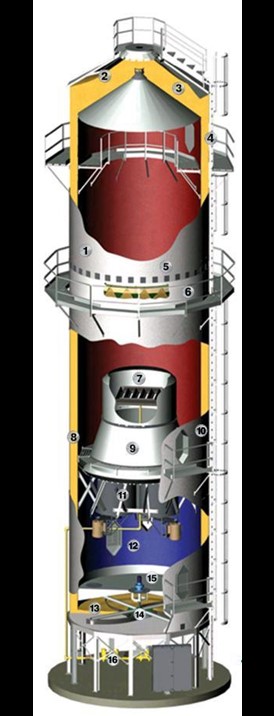

Principle of the Tower Dryer

1) Rotating full/empty sensors for controlling the filling of the buffer section

2)External perforated plates and screws made of stainless steel

3) Perforated plates allow air to move easily through the grain, ensuring uniform drying

4) The grain-turning section is built as a closed plate section to ensure correct heat/air distribution in the air chamber and to prevent dust emission

5) Two cleaning hatches per panel in the grain-turning section make cleaning easy

6) A special reduction cone ensures correct distribution of air through the burner

7) RTD sensors monitor the temperature of the grain and help control the drying process

8) High-quality motors with ATEX certification

9) Adjustable louver doors ensure the correct airflow in the vacuum cooler section

10) Heat recovery is standard and ensures an energy-efficient drying process

11) Robust frame construction ensures sufficient ground clearance and stability

12) The QuadraTouch control system is user-friendly and ensures efficient operation of the dryer

13) XL buffer section made of heavy-duty plates prevents dust emission

14) 324 mm grain chamber width for correct air velocity and efficiency

15) Access ways from platforms allow easy cleaning

16) Maxon® industrial-grade burners are standard

17) Access ways from platforms allow easy internal access for cleaning and maintenance

18) Grain turners move the grain from the center to the outer parts of the grain chambers about halfway through the drying process to ensure uniform moisture content and temperature in the dried crop

19) In-Line Barry Blower® centrifugal fans made to industrial standards are standard

20) The construction and placement of the fans ensure very quiet operation. The specially designed discharge system ensures uniform emptying of the dryer. Continuous moisture measurement at the top and bottom of the dryer ensures very accurate and automatic control of the dried crop’s moisture content

21) Wear parts of the discharge system are made of stainless steel, ensuring a long service life

22) Patented leveling wheels ensure a consistent grain flow

23) The fuel ramp is equipped with Siemens and Maxon components and is fully modulating for easy adjustment and uniform drying air temperature

Tower Dryer